Introduction

Welded wire mesh is made from two different types of materials: mild steel (MS) and galvanized iron (GI). Strong and inflexible, welded wire mesh is created by first laying wires both vertically and horizontally, and then welding each intersection together. Egg baskets, draining racks, fences, and other items are frequently made of it in the agricultural and industrial sectors. It is made of steel wires that cross over one another and are fused together at those intersections to create a structure that resembles a grid.

Mild steel (MS) Weld Mesh

Typically, this kind of weld mesh is composed of various diameters of plain stainless steel wire. It is extensively utilized in many different areas, including industrial application, agricultural fence, and infrastructure and building. Welded mesh is the category. MS is used to build scaffolding, dividers, and reinforce concrete buildings. Fence can be frequently used in obstacles, temporary fence, and boundary fencing. The Industrial has been used to make machinery guards, storage racks, and other items in general industrial settings where great strength is required but little moisture exposure.

Galvanized Iron(GI) Weld Mesh

Galvanized iron plastering wire mesh for use in construction. A strengthening material used for both interior and exterior decorating, plastering mesh is particularly useful for plastering projects. It offers improved traction on the plaster wall. The Content that is made from steel or iron wire that has undergone the galvanization process, which covers it in a layer of zinc.

The Qualities of Corrosion Resistance has a GI weld mesh is perfect for outdoor use because of its superior protection against rust and corrosion from the zinc coating. The Durability is Compared to uncoated mild steel, galvanized iron is more resilient and lasts longer in adverse environments. The Maintenance is done, which is because of its resistance to corrosion, it requires less maintenance. The Aesthetics is suited for situations where appearance counts because of the smooth, glossy sheen that the zinc coating imparts.

MESH

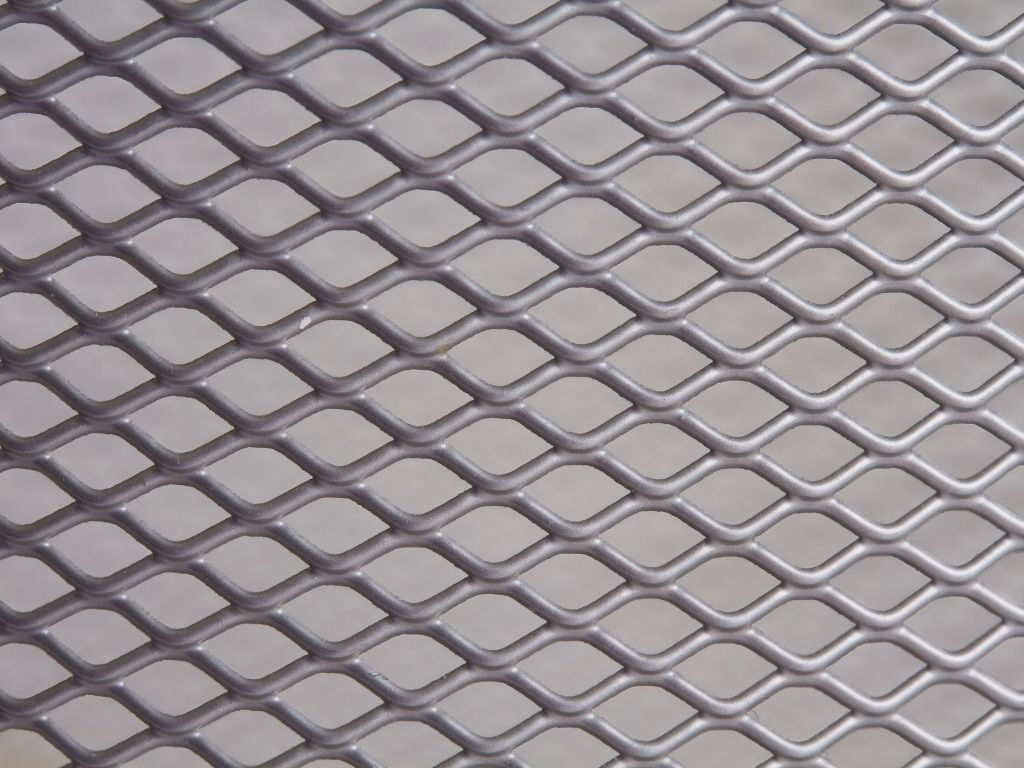

The National Library of Medicine’s Medical Subject Headings (MESH) restricted vocabulary thesaurus provides consistency and uniformity to the indexing and cataloging of biomedical material. Metal wires that have been welded at their intersections are used to create welded wire mesh, or weld mesh. A light gauge product or a heavy gauge product can be created by utilizing wires of varying diameters. Mild steel, galvanized steel, and stainless steel are used in its manufacturing. Mesh layers are categorized using polygons, which allow you to do spatial and attribute queries on the feature layer that is classifying the mesh layer, as well as visually identify distinct sections of the mesh layer and access the attribute data of the classification features.

Applications of Weld Mesh

Although MS welded mesh is robust and resilient, it is susceptible to corrosion, particularly in outdoor settings. Schools, business parks, and locations with tight security frequently employ it. The process of connecting parallel longitudinal wires to cross wires at predetermined intervals creates welded wire mesh. Both horizontal and vertical wires are installed, and each intersection is welded separately. The outcome is a level, flat, sturdy, and stiff mesh.

Welded Wire Mesh

There are various designs for wire mesh, including woven, welded, and PVC coated varieties. These wire meshes are ubiquitous; they are found in gardens, farms, sports fields, and the construction sector. Wire Steel provides a variety of woven and welded wire mesh options to satisfy the diverse requirements of its clientele. All of your structural elements have tensile strength and crack management thanks to welded mesh wire. In construction, steel welded wire mesh is used to give concrete strength and durability. The wire mesh is essential in giving the necessary stability after the concrete cures.

Conclusion

Your unique needs will determine which type of weld mesh—GI or MS. MS weld mesh is a wonderful choice if you need a reasonably priced solution for temporary buildings or interior use. GI weld mesh is a superior option, but, if your project calls for an enduring, corrosion-resistant material or involves outside use. The particular requirements of the application, such as durability, corrosion resistance, or cost, determine the material to be used, such as stainless steel or galvanized steel. Weld mesh provides a dependable and adaptable solution for applications in building, industry, and home improvement.

Recent Comments